Page 1

Loading page image...

Page 2

Loading page image...

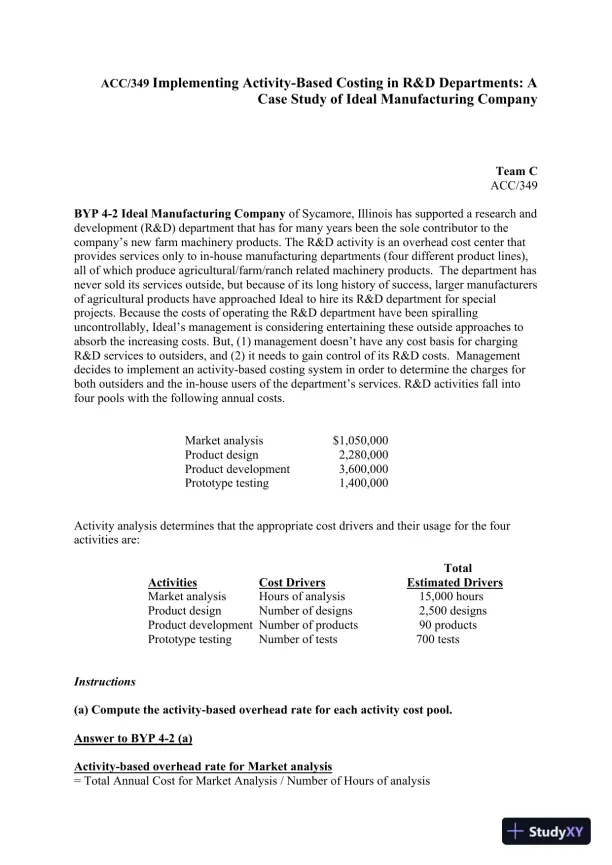

A case study on implementing Activity-Based Costing (ABC) in the R&D department of Ideal Manufacturing Company.

Loading page image...

Loading page image...

This document has 3 pages. Sign in to access the full document!