Page 1

Loading page image...

Page 2

Loading page image...

Page 3

Loading page image...

Page 4

Loading page image...

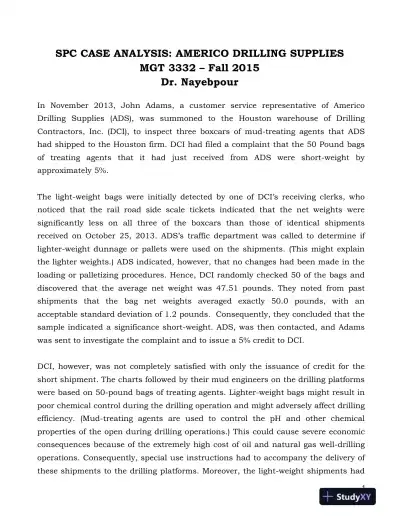

This assignment provides an SPC case analysis for Americo Drilling Supplies, covering quality control methods.

Loading page image...

Loading page image...

Loading page image...

Loading page image...

This document has 10 pages. Sign in to access the full document!