Page 1

Loading page ...

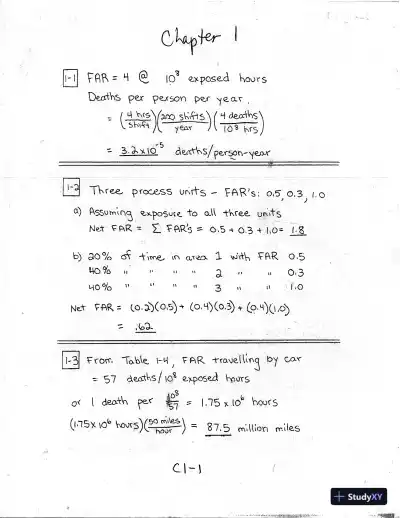

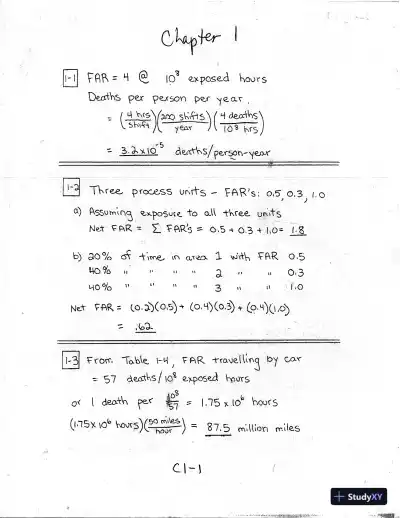

Solution Manual For Chemical Process Safety: Fundamentals With Applications, 3rd Edition is your textbook problem-solver, offering clear and concise solutions to difficult questions.

Loading page ...

This document has 727 pages. Sign in to access the full document!