Page 1

Loading page ...

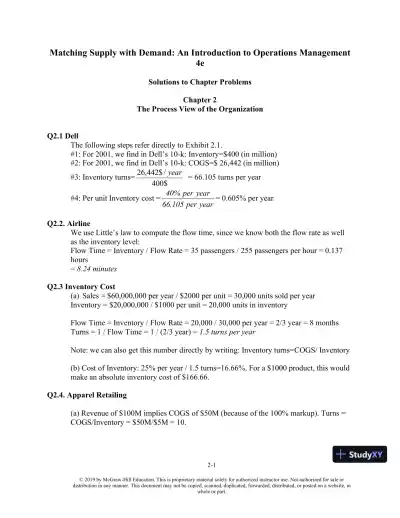

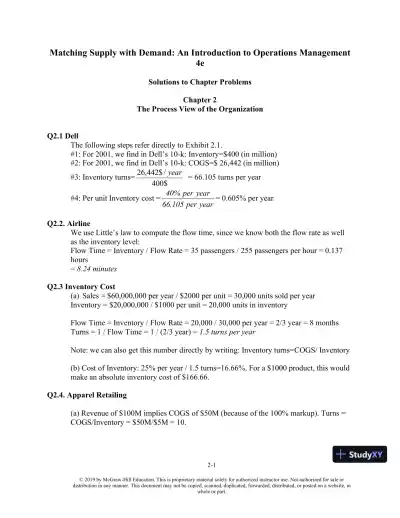

Solution Manual For Matching Supply with Demand: An Introduction to Operations Management, 4th Edition gives you the answers you need, explained in a simple and clear way.

Loading page ...

This document has 76 pages. Sign in to access the full document!